With the rapid development of China's long-distance oil and gas pipeline construction it has great economic and social benefits to timely detect the girth weld and evaluate the safety and reliability of the pipeline to ensure the safety of pipeline transportation. Shantou Goworld's new real-time 3D total-focusing inspection system for pipeline girth welds provides a new solution for pipeline girth welds detection with special scanning tooling displays of 3D images and rapid evaluation of detection results in real time.

1. Pipe girth weld test specimen

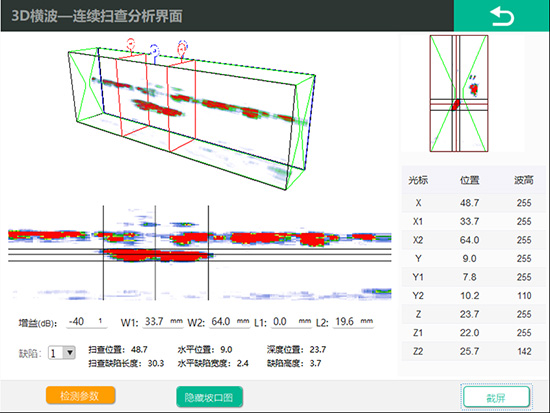

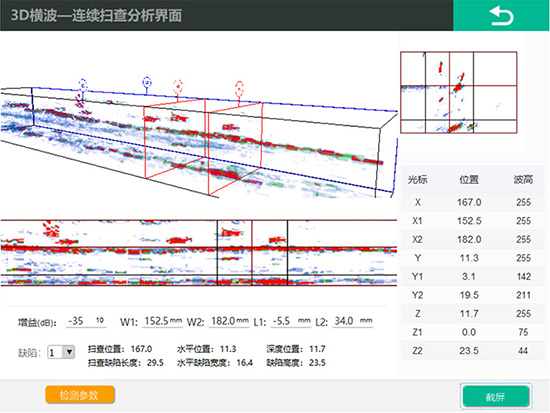

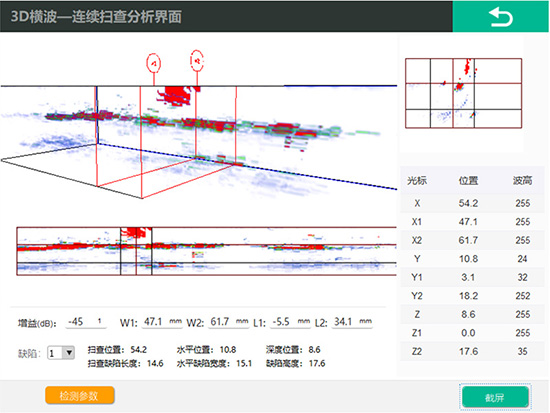

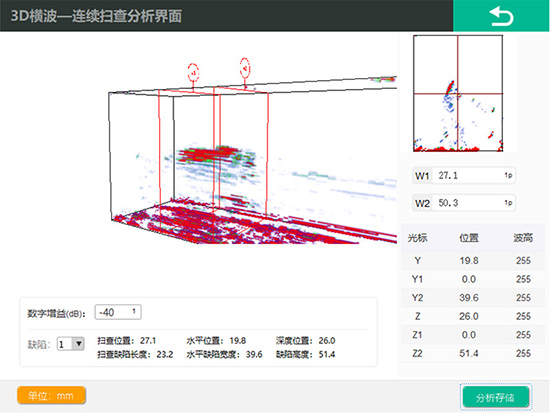

The real-time 3D total-focusing inspection system is adopted to conduct continuous scanning with special chain scanner for pipeline detection. From the 3D continuous scanning images it is easy to judge whether there are defects in the pipeline girth weld. Further on-line analysis combined with a custom weld model can quickly realize the defect location and property judgment.

Continuous scanning of pipeline girth weld specimen

3D continuous scanning imaging of pipeline girth weld specimen

Continuous scanning analysis diagram of pipeline girth weld specimen

2. Long distance pipeline girth weld-- field example

For the long-distance pipeline excavated on site the real time 3D total-focusing inspection system is used with a simple scanning device to perform 3D continuous scanning and imaging detection of the pipeline girth weld.

Inspection site diagram of long distance pipeline girth weld

2.1 Φ 610 × 8.6mm pipe

By using real-time 3D total-focusing imaging detection slag inclusion defects and groove non-fusion defects were found in the pipeline girth weld. In the total-focused 3D image the display feature of slag inclusion defect is intermittent reflection echo image of defect which presents intermittent red image; the display feature of non-fusion defect is area defect image which presents a red image.

3D image of slag inclusion defect

3D imaging of non-fusion defect in groove

2.2 3D imaging of non-fusion defect in groove

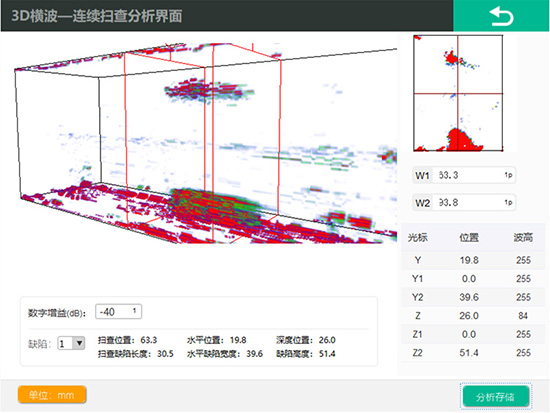

By using real-time 3D total-focusing imaging detection root non-fusion (root undercut) and crack defects were found in the pipeline girth weld. In the total-focused 3D image the display feature of non-fusion defect is an area type defect image; the display feature of crack defect is an area type image and there are scattered images at the upper end of the area type image.

3D image of root non-fusion defect

3D image of crack defect

Pipeline girth weld real-time 3D total-focusing detection simple operation continuous scanning and imaging wide probe sound field coverage no blind spots. The 3D image is displayed in real time following the movement of the probe and different types of defects are clearly visible so as to achieve the detection effect of "see as you see". Online or offline data analysis can be carried out to obtain the size location and other information of defects and defect evaluation can be easily realized.

Real time 3D total-focusing detection simple and reliable process easy and efficient imspection three-dimensional imaging accurate defect location providing a new detection solution for pipeline girth weld.